- 认证

-

- 订阅

-

获取新产品信息

- 最新消息

-

-

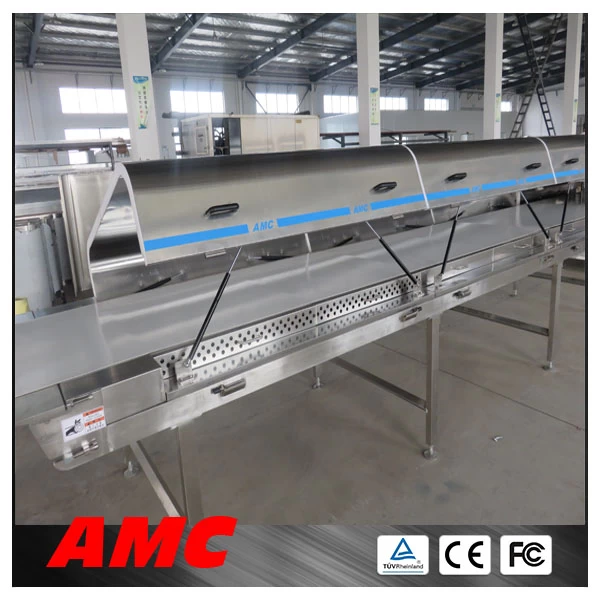

中国高品质冷却隧道食品传送带系统巧克力糖果饼干冷却隧道食品设备

中国食品冷却TUNEL是食品加工行业中用于快速冷却各种食品以延长其保质期并确保食品安全的设备。冷却隧道通常由不锈钢制成,以确保符合食物卫生标准,工作原理是通过将食物通过循环或冷水系统放置在设备中,快速,均匀地降低食物的温度。 -

智能自动包装线的优点及特点

自动包装机是自动化包装生产线的一种设备,它可以自动完成装箱、装箱、打标等工作,大大提高生产效率,降低人工成本。自动包装机广泛应用于各个行业,如食品行业、医药行业、日化用品行业等。 -

食品级冷却隧道的主要作用及注意事项

食品级冷却隧道是食品加工行业中使用的一种设备,用于快速冷却各种食品,以延长其保质期,确保食品安全。冷却隧道通常由不锈钢制成,以确保符合食品卫生标准。其工作原理是通过循环冷水或冷水系统将食品置于设备内部,从而快速、均匀地降低食品的温度。 -

巧克力涂抹机的工作原理及注意事项

巧克力撒布机通常与巧克力裹衣机配套使用,将芝麻、坚果碎等小颗粒撒在涂层和未冷却的巧克力产品的表面上,然后输送到冷却隧道中。该型号应与巧克力包衣机相匹配。 -

巧克力物料搅拌机的工作原理及维护方法

巧克力物料混合机广泛用于混合粉状或湿性、糊状物料,不是将主要辅料按比例混合均匀。该机与物料接触处采用不锈钢材质,叶片与筒体间隙小,搅拌无死角,搅拌轴两端设有密封装置,可防止物料的外合作用,广泛应用于医药、化工、食品等行业。 -

巧克力谷物棒成型机的使用注意事项及优点

巧克力燕麦片/谷物棒制造机主要用于生产巧克力燕麦棒、巧克力谷物棒等巧克力制品。该机在吸收国外技术的基础上进行改进和调整,采用双泵、双混合斗,变频调速,PLC控制系统。 -

巧克力片浇注机如何保持高效运行

巧克力片浇注机是生产小滴状或纽扣状巧克力片的专用设备。可通过PU输送带上的浇注头浇注巧克力浆,并将产品输送到冷却隧道中冷却并自动脱落。具有设定量准确、操作方便、生产能力大等优点。 -

巧克力可可脂融化机工作原理及维护要点

巧克力融化机配备巧克力输送泵和流量计,可用于融化可可脂并将液体输送到巧克力精炼机和精炼机中。该巧克力融化机系列具有电加热和自动控温功能。 -

巧克力球磨机在实际生产中的应用

巧克力球磨机用于球磨巧克力酱。具有产量高、能源成本低、细度均匀等优点。该机可与精炼机或混合机、储罐、巧克力输送泵配套使用,保证连续生产,提高生产效率。它具有自动温度控制功能。 -

如何让巧克力豆机更加高效的工作

巧克力豆制造机主要用于将纯巧克力糊冷轧成各种形状的巧克力豆,如球形、蛋形、MM豆形巧克力豆等。该机配有冷辊、冷却系统、冷却隧道、梁边分离装置。具有生产效率高、重量准确、产品质地和口感好等优点。

-

- 热门产品

- 畅销产品

- 联系我们

-

跨国公司全球战略供应商。

两个自己的工厂用于制造和预组装。

高级工程师负责设计和技术支持。 现在联系

China Supplier 2016 Newest Stainless Steel Cooling Tunnel Machine

- Condition: New

- Place of Origin: Jiangsu, China (Mainland)

- Brand Name: AMC

- Model Number: AMC-CCT89

- Application: Chocolate

- Voltage: 380V/50HZ

- Power(W): 4kw Weight: 3000kg

- Dimension(L*W*H): 22500*1750*750mm

- Certification: TUV

- Warranty: 1 Year

- After-sales Service

- Provided: Overseas service center available

- Material: 304 Stainless Steel

- Name: AMC stainless steel Biscuit bread chocolate cooling tunnel

- Function: cooling chocolate to lower temperature

- Model: double open cover

- Compressor: 15HP

- Keywords: cooling tunnel

- Refrigerant: R407

- Size1: 170000*1750*1000mm as custimzed

- Motor: Siemens/SEW/China brand/others conveyor: PU belt for food

Features:

|

Type |

Air-cooled / Water-cooled |

|

Weight |

150Kg/M |

|

Capacity |

100-2000Kg/Hr |

|

Speed |

Adjustable 1~15 M/min |

|

Voltage |

220V/380V |

|

Power |

10-65KW |

|

Tunnel Temp |

0~10℃ |

|

Material of Frame |

Stainless Steel |

|

Material of Belt |

White PU Belt (Food industry) |

|

Application |

Food Industrial Cooling |

|

Drive Motor |

SEW / CPG 1.1~5.5KW |

|

Compressor |

BITZER / COPELAND 5~25 Hp |

|

Condenser |

BITZER / COPELAND |

|

Warranty |

1 Year |

|

Package |

Wooden Case |

|

Holding Time |

1~60 min |

|

Control Models |

PLC & Touch Panel |

|

Working Temp |

-10~10 ℃ |

|

Common Size |

W=1150/1450/1750(mm) |

Advantage:

a. Specializing in this field for more than 10 years, Have been the Global Supplier of multinational companies.

b. Have own R&D Dept. & Production Equipment.

c. A number of Practical Patents in the Energy Saving and Environmental Protection.

d. CE,TUV, ISO, AQA Certificated.

e. Nice appearance.

f. Unique Design for Easy cleaning & Maintenance.

g. Various of dimensions, customized is available.

h. Precise temperature control by separated zone used.

Benefit:

1. Consistency and flexibility.

2. Innovation.

3. Easy Clean and Maintenance.

4. Nice Appearance.

5. Reliability and Service.

6. Energy Saving and Environmental Protection.

7. Precise temperature control.

Detail Image:

Package:

Wooden Case will be used if no special requirements.

Delivery & Payment:

1. Delivery Time:

60 working days after receiving payment

2.Terms of payment:

50% T/T in advance, the balance shall be paid before the shipment. The above price is based on current exchange rate, if the exchange rate changed 2%, we cannot keep the price.

3. Testing & Training (If you need):

The plant layout design, assembling, installation and debugging, start-up and local team training will be Free at no cost. But the buyer should be responsible for the round-trip air tickets, local transportation, board & lodging, and USD $ 45/day/person for the pocket money to our technicians.

About Us: