- Browse Categories

- Certifications

-

- Subscribe

-

Get new product information

- Latest news

-

-

Customizable Small Food Cooling Conveyor/ Mini Chocolate Cooling Tunnel Machine

-

China Commercial Stainless Steel Double Tower Chocolate Fountain wholesaler

-

China Stainless Steel Small Chocolate Refiner Chocolate Conche Machine Supplier

-

China Automatic Chocolate Coating Enrobing Machine with Cooling Tunnel Factory

Chocolate enrobing machine is the dedicated equipment for making assorted chocolate products with functions of whole coating, single-sided coating, partial coating and cooling. -

China High Quality Cooling Tunnel Food Conveyor System Chocolate candy biscult Cooling Tunnel for Food Equipment

China Food cooling tunel is a device used in the food processing industry to quickly cool various foods to extend their shelf life and ensure food safety. Cooling tunnels are usually made of stainless steel to ensure compliance with food hygiene standards, The working principle is to quickly and evenly reduce the temperaure of the food by placing it inside the equipment through a circulating cold or cold water system. -

Advantages and characteristics of intelligent automatic packaging line

Automatic packaging machine is a kind of equipment for automatic packaging production line, it can automatically complete the packaging, packaging, marking and other work, greatly improve production efficiency and reduce labor costs. Automatic packaging machines are widely used in various industries, such as the food industry, pharmaceutical industry, daily chemical products industry, etc. -

The main functions and precautions of food grade cooling tunnel

Food grade cooling tunnel is a device used in the food processing industry to quickly cool various foods to extend their shelf life and ensure food safety. Cooling tunnels are usually made of stainless steel to ensure compliance with food hygiene standards. The working principle is to quickly and evenly reduce the temperature of the food by placing it inside the equipment through a circulating cold or cold water system. -

Working principle and precautions of chocolate spreader machine

Chocolate Spreading Machine is usually used along with chocolate enrobing machine for spreading the small items such as sesame and crushed nuts on the surface of coated and un-cooled chocolate products before conveying into the cooling tunnel. The model should match the chocolate enrobing machine. -

The working principle and maintenance method of chocolate material mixer

Chocolate material mixer is widely used in mixing powder or wet, paste materials, is not the proportion of main auxiliary materials mixed evenly. The machine is made of stainless steel at the contact point with the material, the clearance between the blade and the barrel is small, the mixing has no dead Angle, and the two ends of the mixing shaft are provided with a sealing device, which can prevent the external cooperation of the material, and is widely used in pharmaceutical, chemical, food and other industries. -

The use of chocolate cereal bar forming machine precautions and advantages

Chocolate oatmeal/cereal making machine is mainly used for the production of chocolate oatmeal bar, chocolate cereal bar and other chocolate products. This machine has made improvement and adjustment on the base of foreign technology, which adopts double pumps and double mixing hoppers with frequency speed control and PLC control system.

-

- Hot Products

- Best Selling Products

- Contact Us

-

Globe strategic supplier of multinational companies.

Two of own plant for manufacture and pre-assembly.

Senior engineers for design and technical support. Contact Now

Customized stainless steel high performance multifunction intelligent conveyor system

- Condition:New

- Type:Bucket Conveyor

- Material:Stainless Steel

- Material Feature:Fire Resistant

- Structure:Chain Conveyor

- Load Capacity:Customized

- Place of Origin:Jiangsu, China (Mainland)

- Brand Name:AMC intelligent conveyor system

- Model Number:AMC-101

- Voltage:380V50HZ or As Customized

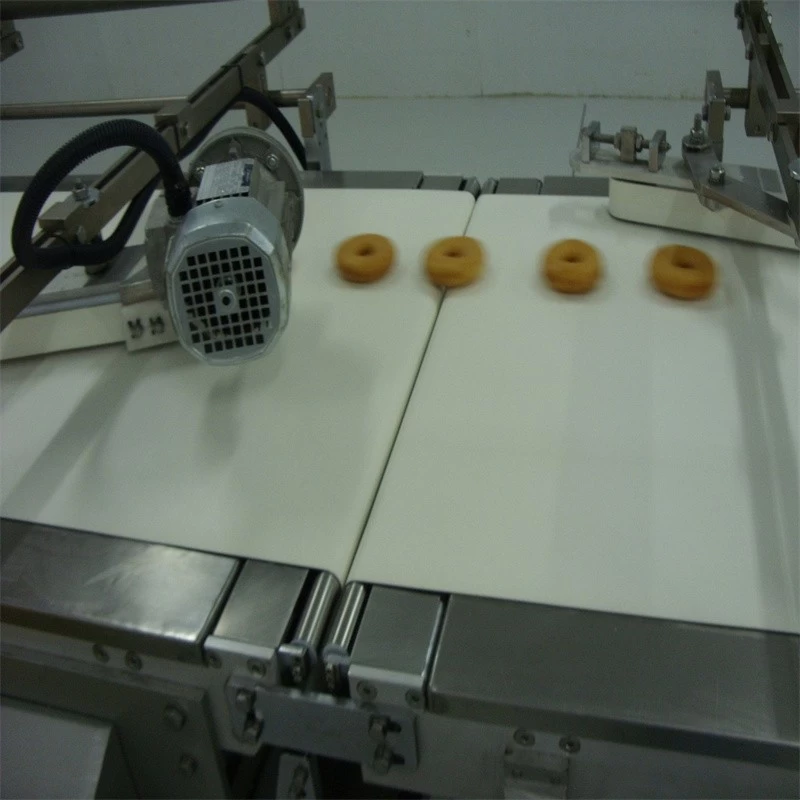

Customized stainless steel high performance multifunction intelligent conveyor system

Product Features:

1.Running smoothly,good explosion-proof.

2.Easy installation,long service life.

3.Lowest maintenance cost.

4.Capacity adjustable,motor manual or automatic.

5.Simple structure,convent operation and maintenance.

6.All design and dimension can be customized.

7.Smooth belt surface.

8.Side guard is available.

9.Easy to maintain and clean.

Product Show:

About Us:

AMC System Technology (Suzhou) Co., Ltd was established in 2003. Our main equipment includes food

machinery, cooling tunnels, refrigeration systems, robot assembly and packaging systems, and intelligent

conveying systems. Our products cover fields such as food, health, new energy, photon communication,

3C,automotive components etc.

We are the core supplier for companies such as Kraft, Mondelez, Nestle, GM, Henkel, Taiyo Ink and

Trans-Matic, etc. AMC has 15 years of global trade experience. Currently, AMC products have been

exported to more than 33 countries.

AMC believes in innovation, and we have become a high-tech enterprise, with a number of independent

intellectual properties and patents and inventions. AMC adheres to a corporate culture of honesty,

respect, openness, and innovation. We warmly welcome domestic and foreign valuable customers.

Our Factory:

Certification:

Package:

Our Advantages:

- Global supplier of 8 largest food companies in the world.

- 15 years of experience in international trade.

- 20 years of experience in cooling tunnel field.

- Customers from more than 33 countries all over the World.

- 3 plants for manufacture and pre-assembly.

Contact Us:

- AMC System Technology (Suzhou) Co., Ltd.

- Suzhou Plant: 688 Lingshan Road, Wuzhong District, Suzhou, Jiangsu Province.

- Suzhou Office: Room 1218, Phase III, SeG Electronics Market, No. 588 Binhe Road, High-tech Zone, Suzhou City, Jiangsu Province.

- Tel: +86-512-6809 6318

- M/T: +86 138 1488 6998

- Fax: +86-512-6809 1880

- E-mail: andy@amccv.com

- E-mail: zbsnd@hotmail.com

- Http:// www.coolingtunnelsystem.com