- Browse Categories

- Certifications

-

- Subscribe

-

Get new product information

- Latest news

-

-

China High Quality Cooling Tunnel Food Conveyor System Chocolate candy biscult Cooling Tunnel for Food Equipment

China Food cooling tunel is a device used in the food processing industry to quickly cool various foods to extend their shelf life and ensure food safety. Cooling tunnels are usually made of stainless steel to ensure compliance with food hygiene standards, The working principle is to quickly and evenly reduce the temperaure of the food by placing it inside the equipment through a circulating cold or cold water system. -

Advantages and characteristics of intelligent automatic packaging line

Automatic packaging machine is a kind of equipment for automatic packaging production line, it can automatically complete the packaging, packaging, marking and other work, greatly improve production efficiency and reduce labor costs. Automatic packaging machines are widely used in various industries, such as the food industry, pharmaceutical industry, daily chemical products industry, etc. -

The main functions and precautions of food grade cooling tunnel

Food grade cooling tunnel is a device used in the food processing industry to quickly cool various foods to extend their shelf life and ensure food safety. Cooling tunnels are usually made of stainless steel to ensure compliance with food hygiene standards. The working principle is to quickly and evenly reduce the temperature of the food by placing it inside the equipment through a circulating cold or cold water system. -

Working principle and precautions of chocolate spreader machine

Chocolate Spreading Machine is usually used along with chocolate enrobing machine for spreading the small items such as sesame and crushed nuts on the surface of coated and un-cooled chocolate products before conveying into the cooling tunnel. The model should match the chocolate enrobing machine. -

The working principle and maintenance method of chocolate material mixer

Chocolate material mixer is widely used in mixing powder or wet, paste materials, is not the proportion of main auxiliary materials mixed evenly. The machine is made of stainless steel at the contact point with the material, the clearance between the blade and the barrel is small, the mixing has no dead Angle, and the two ends of the mixing shaft are provided with a sealing device, which can prevent the external cooperation of the material, and is widely used in pharmaceutical, chemical, food and other industries. -

The use of chocolate cereal bar forming machine precautions and advantages

Chocolate oatmeal/cereal making machine is mainly used for the production of chocolate oatmeal bar, chocolate cereal bar and other chocolate products. This machine has made improvement and adjustment on the base of foreign technology, which adopts double pumps and double mixing hoppers with frequency speed control and PLC control system. -

How does the chocolate chip depositing machine keep running efficiently

Chocolate Chip Depositing Machine is the dedicated equipment for the production of chocolate chip in small drop-shape or button shape. It can be used to deposit chocolate pastes through depositing head on the PU conveyor belt and convey the products into the cooling tunnel for cooling down and automatic shedding. It has advantages of accurate amount set, easy operation and large production capacity. -

Working principle and maintenance points of chocolate cocoa butter melting machine

Chocolate Melting Machine can be used for melting cocoa butter and delivering the liquor into the chocolate refiner and conche when equipped with chocolate delivery pump and flow meter.This chocolate melting machine series has electric heating and automatic temperature control. -

The application of chocolate ball milling machine in actual production

Chocolate Ball Milling Machine is used for ball milling chocolate pastes. It has the advantages of high production output, low energy cost, even fineness and etc..This machine can be used along with conche or mixer, storage tank and chocolate delivery pumps to ensure continuous production and improve production efficiency. It has automatic temperature control. -

How to make the chocolate bean making machine more efficient work

Chocolate Bean Making Machine is mainly used for cold rolling the pure chocolate paste into various shapes of chocolate beans, such as the spherical, the egg-shaped, the MM bean shaped chocolate beans and so on. This machine is equipped with cold roller, cooling system, cooling tunnel, beam rim separation unit. It has advantages of high production efficiency, weight accuracy, products with good texture and taste, and etc.

-

- Hot Products

- Best Selling Products

- Contact Us

-

Globe strategic supplier of multinational companies.

Two of own plant for manufacture and pre-assembly.

Senior engineers for design and technical support. Contact Now

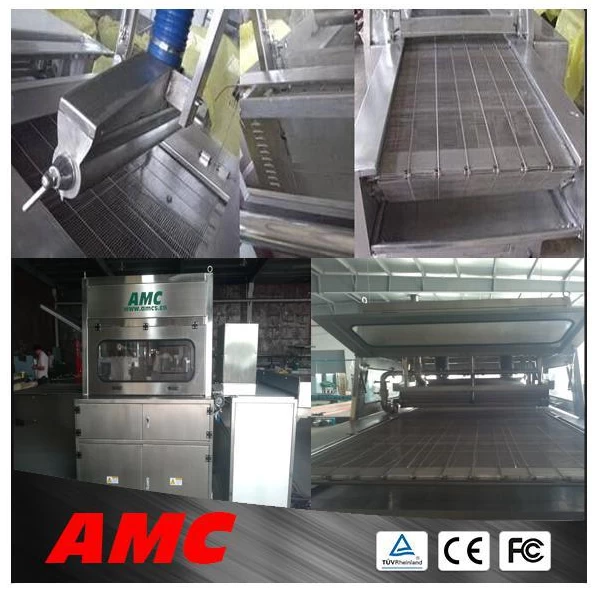

AMC Leading manufacturers easy operation full-automatic chocolate enrobing and coating machine

- Condition: New

- Place of Origin: Jiangsu, China (Mainland)

- Brand Name: AMC-Chocolate Enrobing Machine

- Model Number: ATY400

- Application: Chocolate

- Refrigeration unit(set): 3p2set

- Power(W): 7.5KW

- Weight: 2000KG

- Dimension(L*W*H): Lx950x1800mm

Chocolate enrobing machine

Brief Introduction:

It is for a special purpose of producing assorted chocolates. It can coat thick chocolate syrup on many kinds of food, such as candy, pastry, biscuit etc. to form chocolates with various unique flavors.

Technical Parameter:

Frame material: stainless steel

Wire mesh and belt width(mm): 400

Wire mesh and belt speed(m/min): 1-10

Refrigeration unit(set): 3p 2set

Cooling tunnel length(m): 10

Cooling tunnel temperature(℃):2-10

Total power(kw):12.06

Weight(kg):2000

Dimensions(mm):14200*950*1800 (* Length is related to the length of the cooling tunnel)

Certification: CE,ISO,TUV

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas Tunnel

Advantage:

a. Specializing in this field for more than 10 years, we’ve been the Global Supplier of multinational companies.

b. Have own R&D Dept. & Production Equipment.

c. A number of Practical Patents in the Energy Saving and Environmental Protection.

d. CE,TUV, ISO, AQA Certificated.

e. Nice appearance.

f. Unique Design for Cover, which can be opened double sides.

g. Various of dimensions, customized is available.

h. Precise temperature control by separated zones used.

I . Precision engineering.

J. Radiation cooling.

Benefit:

1. More professional and experienced suggestion and solution will be given.

2. Innovation, our R & D dept are always work for a better solution.

3. Energy Saving and Environmental Protection.

4. Reliable and safe.

5. Nice Appearance.

6. Easy Clean and Maintenance.

7. Unique Design as you request.

8. Precise temperature control.

9. Uniform coating of products.

Detail Image: