- Browse Categories

- Certifications

-

- Subscribe

-

Get new product information

- Latest news

-

-

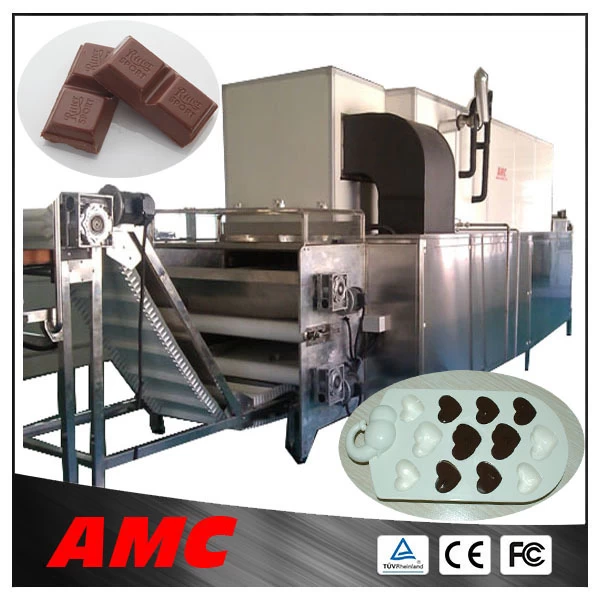

Customizable Small Food Cooling Conveyor/ Mini Chocolate Cooling Tunnel Machine

-

China Commercial Stainless Steel Double Tower Chocolate Fountain wholesaler

-

China Stainless Steel Small Chocolate Refiner Chocolate Conche Machine Supplier

-

China Automatic Chocolate Coating Enrobing Machine with Cooling Tunnel Factory

Chocolate enrobing machine is the dedicated equipment for making assorted chocolate products with functions of whole coating, single-sided coating, partial coating and cooling. -

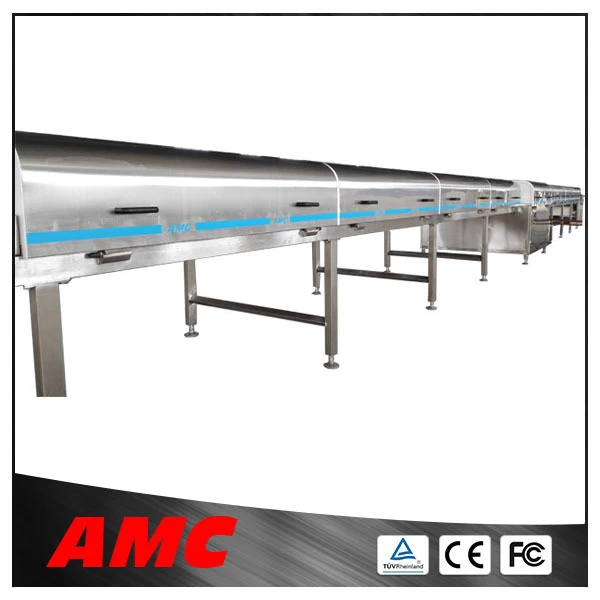

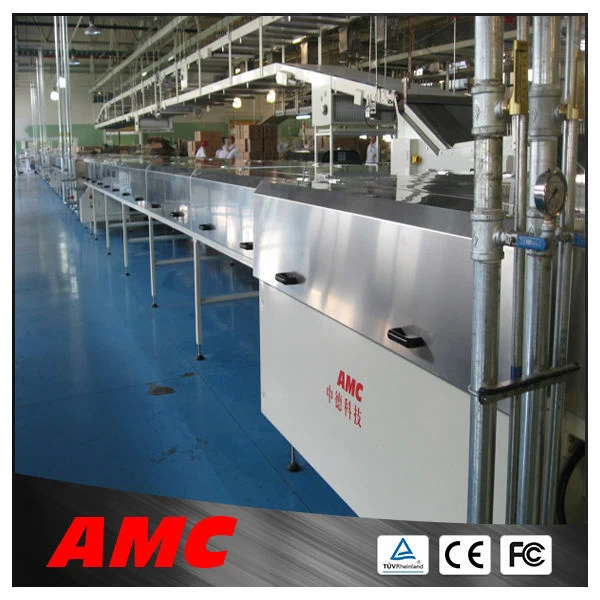

China High Quality Cooling Tunnel Food Conveyor System Chocolate candy biscult Cooling Tunnel for Food Equipment

China Food cooling tunel is a device used in the food processing industry to quickly cool various foods to extend their shelf life and ensure food safety. Cooling tunnels are usually made of stainless steel to ensure compliance with food hygiene standards, The working principle is to quickly and evenly reduce the temperaure of the food by placing it inside the equipment through a circulating cold or cold water system. -

Advantages and characteristics of intelligent automatic packaging line

Automatic packaging machine is a kind of equipment for automatic packaging production line, it can automatically complete the packaging, packaging, marking and other work, greatly improve production efficiency and reduce labor costs. Automatic packaging machines are widely used in various industries, such as the food industry, pharmaceutical industry, daily chemical products industry, etc. -

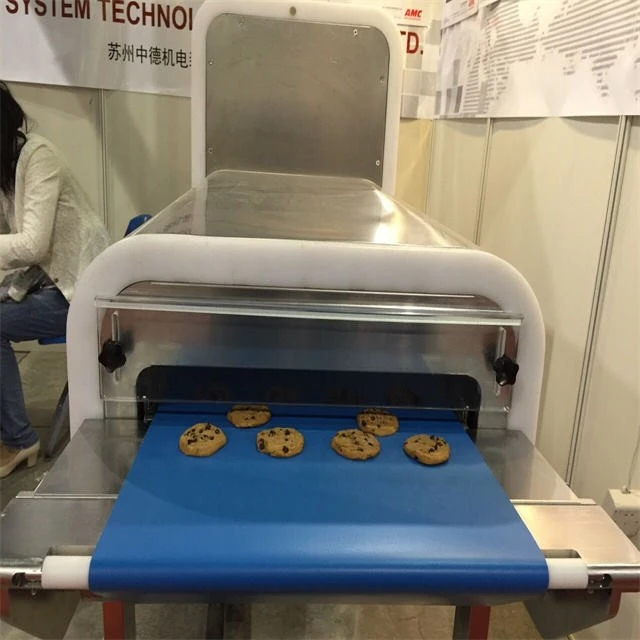

The main functions and precautions of food grade cooling tunnel

Food grade cooling tunnel is a device used in the food processing industry to quickly cool various foods to extend their shelf life and ensure food safety. Cooling tunnels are usually made of stainless steel to ensure compliance with food hygiene standards. The working principle is to quickly and evenly reduce the temperature of the food by placing it inside the equipment through a circulating cold or cold water system. -

Working principle and precautions of chocolate spreader machine

Chocolate Spreading Machine is usually used along with chocolate enrobing machine for spreading the small items such as sesame and crushed nuts on the surface of coated and un-cooled chocolate products before conveying into the cooling tunnel. The model should match the chocolate enrobing machine. -

The working principle and maintenance method of chocolate material mixer

Chocolate material mixer is widely used in mixing powder or wet, paste materials, is not the proportion of main auxiliary materials mixed evenly. The machine is made of stainless steel at the contact point with the material, the clearance between the blade and the barrel is small, the mixing has no dead Angle, and the two ends of the mixing shaft are provided with a sealing device, which can prevent the external cooperation of the material, and is widely used in pharmaceutical, chemical, food and other industries. -

The use of chocolate cereal bar forming machine precautions and advantages

Chocolate oatmeal/cereal making machine is mainly used for the production of chocolate oatmeal bar, chocolate cereal bar and other chocolate products. This machine has made improvement and adjustment on the base of foreign technology, which adopts double pumps and double mixing hoppers with frequency speed control and PLC control system.

-

- Hot Products

- Best Selling Products

- Contact Us

-

Globe strategic supplier of multinational companies.

Two of own plant for manufacture and pre-assembly.

Senior engineers for design and technical support. Contact Now

high quality wafer chocolate cooling tunnel

- Type Air-cooled / Water-cooled

- Weight 150Kg/Meter

- Capacity 100-2000Kg/Hr

- Speed Adjustable 1~15 M/min

- Voltage 220V/380V

- Power 10-45KW

- Tunnel Temp 0~10℃

- Material of Frame Stainless Steel

- Material of Belt White PU Belt (Food industry Chemical)

- Application Food,Industrial,Chemical,Leechdom Cooling

- Drive Motor SEW / CPG 1.1~5.5KW

- Compressor BITZER / COPELAND 5~25 Hp

- Condenser BITZER / COPELAND

- Warranty 1 Year

- Package Wooden Case

- Holding Time 1~60 min

- Control Models PLC & Touch Panel

- Working Temp -10~10 ℃

- Common Size W=1150/1450/1750(mm)

Chocolate Cooling Tunnel System is applied to many different kind of food,such as wafer chocolate,biscuit,candy,duck,beverage,and so on.

Technical parameter:

Type Air-cooled / Water-cooled Weight 150Kg/Meter Capacity 100-2000Kg/Hr Speed Adjustable 1~15 M/min Voltage 220V/380V Power 10-45KW Tunnel Temp 0~10℃ Material of Frame Stainless Steel Material of Belt White PU Belt (Food industry Chemical) Application Food,Industrial,Chemical,Leechdom Cooling Drive Motor SEW / CPG 1.1~5.5KW Compressor BITZER / COPELAND 5~25 Hp Condenser BITZER / COPELAND Warranty 1 Year Package Wooden Case Holding Time 1~60 min Control Models PLC & Touch Panel Working Temp -10~10 ℃ Common Size W=1150/1450/1750(mm)

Detailed picture:

Advantage:

a. Specializing in this field for more than 10 years, Have been the Global Supplier of multinational companies.

b. Have own R&D Dept. & Production Equipment.

c. A number of Practical Patents in the Energy Saving and Environmental Protection.

d. CE,TUV, ISO, AQA Certificated.

e. Nice appearance.

f. Unique Design for Easy cleaning & Maintenance.

g. Various of dimensions, customized is available.

h. Precise temperature control by separated zone used.

Delivery & Payment:

1. Delivery Time:

Within 60 Days upon the receipt of the deposit.

2.Terms of payment:

50% T/T in advance, the balance shall be paid before the shipment.

The above price is based on current exchange rate,

if the exchange rate changed 2%, we cannot keep the price.

3. Testing & Training (If you need):

The plant layout design, assembling, installation and debugging,

startup and local team training will be Free at no cost. But the buyer shouldbe responsible for the round-trip air tickets, local transportation, board & lodging, and USD $ 45/day/person for the

pocket money to our technicians.