will you be safe in using conveyor and how to be safe ?

You'll be safe Conveyor Cause of the accident control and improvements?

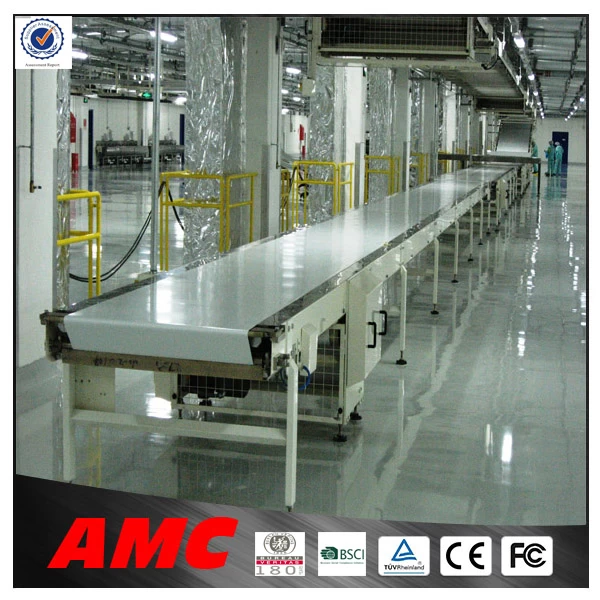

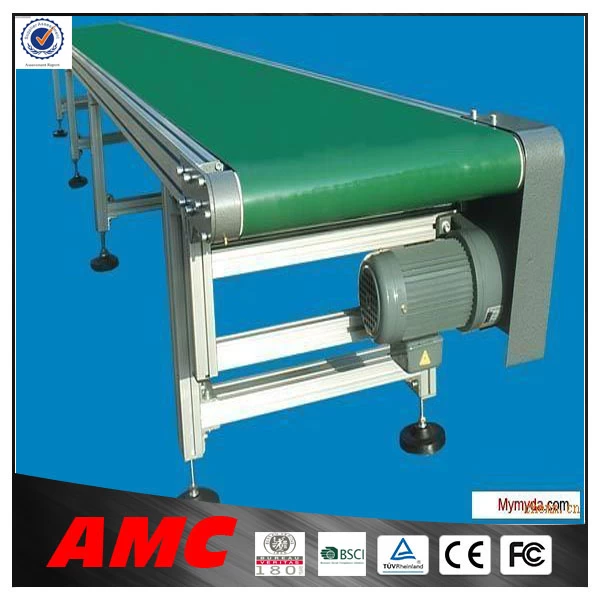

With the development of modern society, the coal industry has also been a lot of unprecedented development, with production capacity increases, the comprehensive mechanization are also constantly upgrading, so that belt use is also growing. In the coal industry, many coal mines have adopted a one-stop delivery. Due to the different types of mines and special operating environment, production conditions are relatively poor, with practices and a lack of transportation and production technology management, so that led to the belt conveyor there are many accidents, serious and even endanger the lives of coal miners. Therefore, it is necessary cause of the accident, so that the conveyor belt to explore and find solutions from technical and production management. Belt conveyors cause of the accident:

(1) the occurrence of injuries, mainly due to illegal operations. ① illegally through the conveyor belt. ② illegal multiplication belt conveyor. ③ Belt conveyors While some people can take, but not perfect protection for offside. ④ Due to poor management, resulting in belt conveyors or the tear tape, it can be divided into two reasons: because the driver's job is not to strengthen the management system, resulting from the normal track deviation first serious band, but there is no corresponding safety device . Second, the metal band interference, or gangue direct hit belt conveyors

(2) a belt fire. In some incidents, the seat belt fire wounded most people, there are three factors: First, there is no complete protection, maintenance, illegible friction belt and driving roller plus generated by the external environment led to a fire; second, During use, the use of substandard materials, such as hydraulic coupling, resulting in fire accidents injector; third, not in accordance with the relevant provisions of the flame retardant used, resulting in a friction fire.

(3) decrease of belt slipping accidents. Inadequate facilities due to a slip belt slipped, Inclined Drift angle is relatively large, overload, leading to accidents; belt slippage was mainly due to large with a load or loose belt or waistband blockage, killing five effective measures to prevent accidents: can be divided two aspects: first, in terms of technical improvements measures: ① To prevent fire belts, conveyor belts can be added automatically shut down, or slide can sprinklers, after the heat added to the cooling effect. ② conveyor belt Inclined Drift angle calculation, the belt will not have to see the conditions of decline, does not meet the conditions, you can refuse the extra belt control equipment. Secondly, in the production and management improvements. ① should conscientiously implement personal responsibility. Driver to drive business training, strengthening vocational driver's management to improve service quality. If you find a problem, we want to improve the timeliness. ② selection of materials science, selection and use of qualified hydraulic coupling medium flame and firebreaks to arrange for professionals to regularly check the belt ③ machine regularly maintained to ensure the normal operation of the belt conveyor. ④ Not all coal belt conveyor can be people, people who can not take, should be strictly prohibited. ⑤ belts should be kept clean, so there is no water, no dirt, no impurities, and has a fire hose and fire extinguishers.